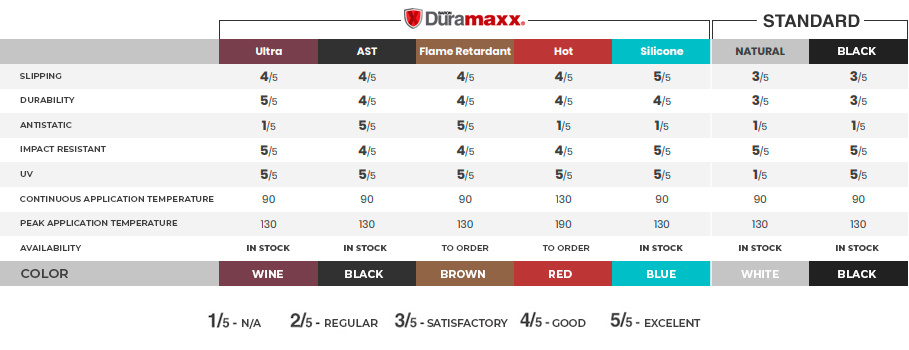

Duramaxx, Baron’s exclusive high-performance line of linings, is suitable for heavy industrial use and can be used in chutes, silos, guides, spouts and mobile mining equipments (such as trucks, wheel loaders, tractors and so on).

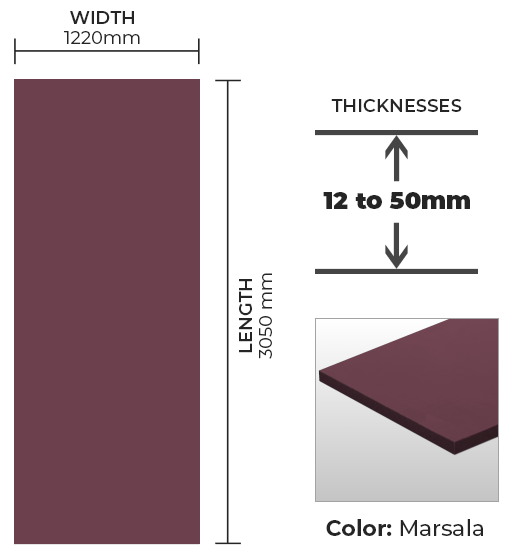

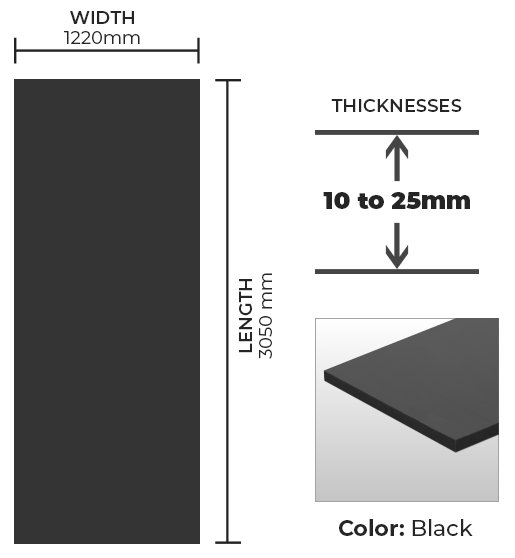

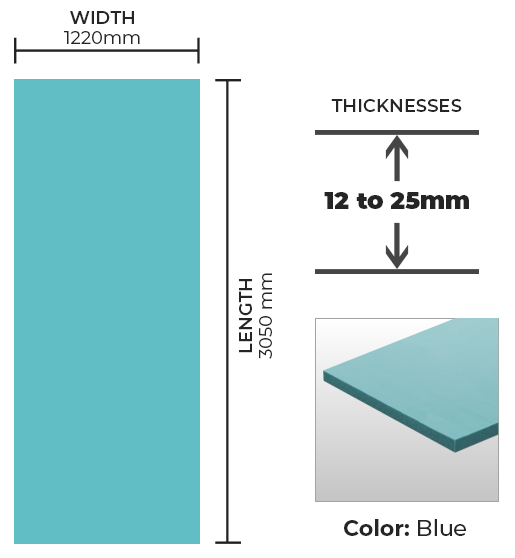

Manufactured with UHMW certified resins, with a molar mass greater than 8.0 million g/mol, the exclusive Baron lining has abrasion resistance far superior to common UHMWs in the market and it’s found in different versions (check the image below).

In today’s blog post, you will know all Duramaxx versions and their respective indications. Shall we?

Duramaxx Ultra: abrasion resistance

Due to its crosslined molecular structure and additive of functional charges, Duramaxx Ultra is best used when high resistance to abrasion is required.

The lining has an lifespan greater than 30% compared to UHMW Type A, optimizes cost-benefit and is more commonly used in more abrasive bulk systems, such as iron ore, sand and bauxite ore.

Duramaxx Ultra is suitable for:

- Transport trucks

- Off-Road Trucks

- Scrapers

- Hydraulic excavators

- Tractors

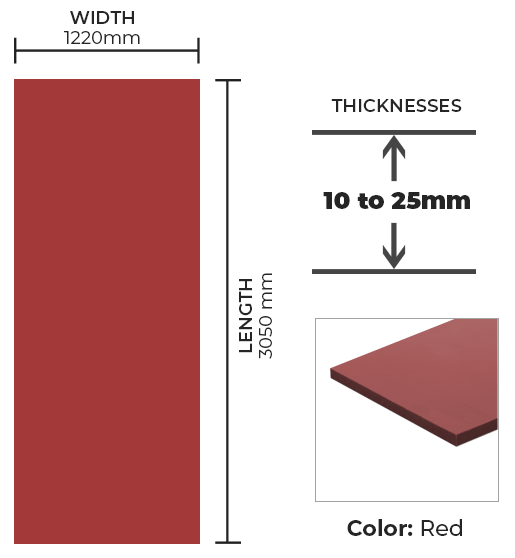

Duramaxx Hot: high temperatures

Duramaxx Hot is composed of UHMW modified with antioxidants, which reduces the oxidation rate at temperatures up to 130°C for continuous use or up to 190°C at peak temperature, maintaining its physicochemical properties.

With a very low friction coefficient, it can be used in the food industry, conveyor belts close to heat sources, asphalt truck linings and coal equipment linings.

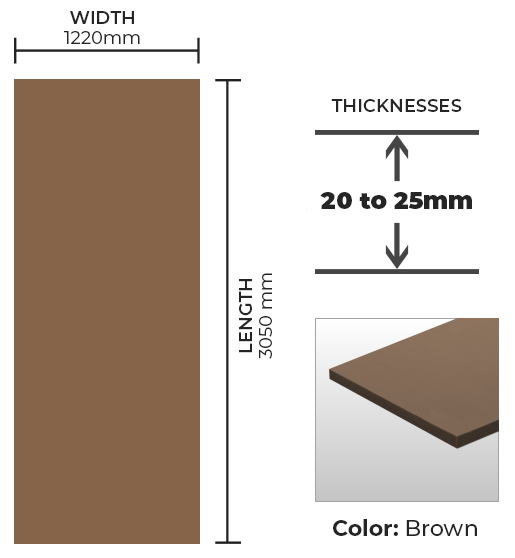

Duramaxx Flame Retardant: risk of flame spread

Modified UHMW with flame retardant characteristics, Duramaxx Flame Retardant is designed for applications with potential exposure to combustible environments, or equipment with fire or explosion hazards.

It does not propagate flame and complies with the UL94 standard, in flame class V-0

Duramaxx Antistac: static charges

Best suited for silos and confined environments of grains, sugar, fertilizers, among others, Duramaxx Antistac is ideal for situations where there is a risk of electrical discharges caused by static charge accumulation.

Through the additivation of conductive loads, Duramaxx AST has antistatic properties, providing safety and high fluidity for the systems where it is used.

Duramaxx Silicone: high lubricity

Additivated with functional oils (Oil Filled), Duramaxx Silicone is the product with the lowest friction coefficient available on the market, ideal for situations where clogging and agglomerations are common.

It is the best solution for environments with less abrasive bulk and fine dust.

Are you in doubt which Duramaxx is best suited for your company? Get in touch with our team through WhatsApp by clicking here!