UHMW is a polyethylene superior to other thermoplastics in terms of abrasion resistance, impact fracture and cracking. Other than that, the product has low friction coefficient, is non-toxic and has excellent chemical resistance.

In today’s blog post, we will learn whats types of UHMW are avaliable in the market, understand the technical characteristics of each and find out which is the best option for your company.

What are the types of UHMW and their technical characteristics?

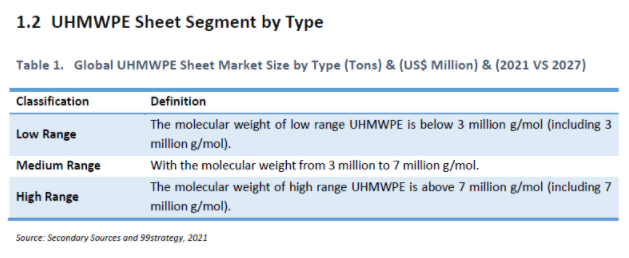

Basically, the UHMW can be classified among 3 groups: UHMW Low Range, UHMW Medium Range and UHMW High Range.

As we see in the image above, the UHMW Low Range has molar mass less than 3 million g/mol, the UHMW Medium Range varies between 3 and milion g/mol and the UHMW High Range has above milion g/mol.

It is valid to point out that the unit of g/mol (grams per mol) is a measure of the average length of the molecular chain that reflects differentiated characteristics. This specification of the resin we demonstrated above gives the material greater resistance to abrasion, that is, the greater the molar mass, the greater the wear resistance (the UHMW High Range is the most resistant).

What is the Best option for your company?

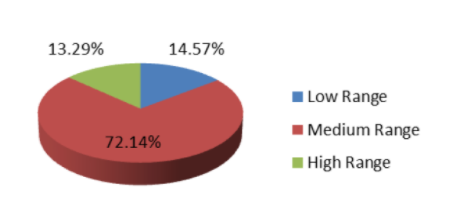

Only 13% of the world’s UHMW are classified as High Range, tougher version of the material.The majority found on the market (71,14%) belongs to the Medium Range group, having between 3 and 7 million g/mol.

The Duramaxx, exclusive Baron product, is manufactured with 100% UHMW High Range resin and specially additivated for maximum abrasion resistance, which doubles the lifespan compared to the regular UHMWs in the market.

For this reason, its quality is considerably higher and its use is indicated for higher abrasion resistance applications (such as mining, fertilizer industries, steel industries, railways, harbors, among others).

The Duramaxx comes with certificate and it is na original Baron product. Get in touch to guarantee to your processes all the advantages of using Duramaxx.